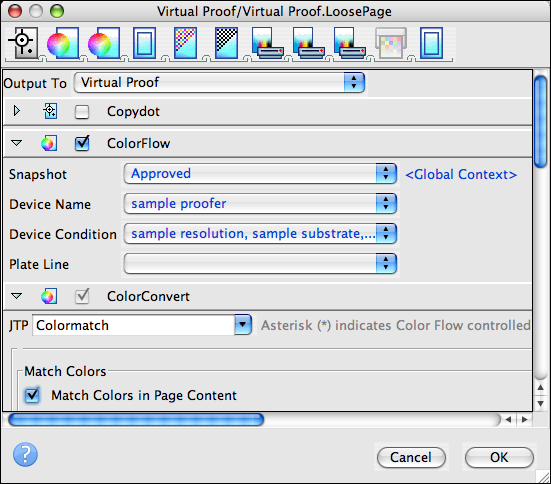

The ColorFlow section in a Prinergy output process template, identifies how ColorFlow settings will be applied during output.

Prinergy output process templates include:

- Loose 1-Up Artwork Output

- Layout Output

- Final Output

The color setup used during output is the one that was assigned to the PDF when they were refined—that is, either the color setup specified in the refine process template that was used or the job's default color setup.

When you configure the ColorFlow settings in an output process template, you can make the following selections:

Snapshot—A ColorFlow snapshot captures the state of the entire color database, making its elements available to the workflow and providing a convenient backup. The snapshots feature makes it unnecessary for you to manually save and name multiple versions of your color control elements after adjusting them. At any time, you can revert to the state of a previous snapshot in the ColorFlow software. When you have completed your work in ColorFlow to a certain level and you are satisfied with the elements in color setups, you will mark a snapshot as Approved.

Device Name—An individual occurrence of a physical device that captures or produces an image. Devices have a type and customer-specified properties, such as a name and location in the plant. Because the declaration of a device does not include its operating conditions—such as ink selection, type of screening, and paper—you cannot measure the color response of a device on its own.

Device Condition—A combination of a device and the operating conditions in which the device captures or produces an image. A device condition has a known color response. Device conditions can be divided into groups such as print conditions (press and proofer devices), capture conditions (scanner and camera devices), and reference print conditions (industry specifications). A device condition can include more than one device if all the devices are the same device type, they use the same consumables and operational settings, and they can be calibrated to yield the same color response.

Plate Line—You establish the bahavior of a particular plate, screening, and plating line by plating a tint ramp, manually measuring the resulting dot area on the plate, and entering the values in the Plate Setups dialog box in the ColorFlow software. A ColorFlow plate line is associated with only one plate setup. In your shop, you may use a platesetter and chemistry to process several different screenings. To model this, in ColorFlow, create similar plate lines in the other plate setups. You can name them to match the equipment in your plant. You may want to create several plate lines to indicate when chemistry changes occur. For example, if you routinely change solutions on Mondays, you might create different ColorFlow plate lines for Monday, Wednesday, and Friday.