In this section you will learn how to use the PRINERGY Portal: Ink Analytics Service: Actual Ink Usage

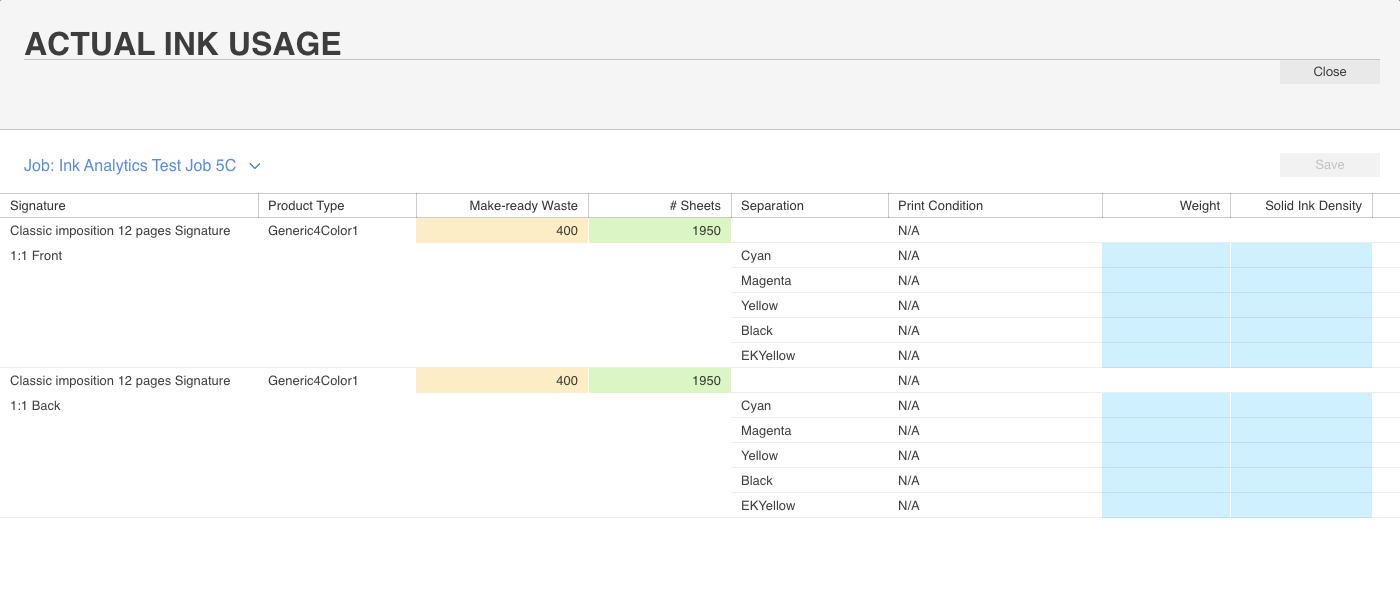

Actual Ink Usage

Use the Actual Ink Usage dashboard to enter ink values recorded after a job is printed. Each value is populated into a database that tracks accuracy between Ink Estimation and actual ink used. Ultimately, allowing you to see trends over time and adjust Ink Usage Mileage Factors to better align estimates with actual ink usage in your plant.

Setting and recording Actual Ink Usage is only available for imposed jobs, as Print Conditions are only assigned at the Imposition Level. Loose Page output does not collectively record how the jobs were imposed or assigned Print Conditions.

Recording Actual Ink Usage for a Job

To record Actual Ink Usage:

- Select the target job and enter the amount of ink used in the Weight column.

- Enter the recorded Solid Ink Density for each color.

Recording Solid Ink Densities acts as a quality control tracker ensuring that Solid Ink Densities are consistent over time, and allowing you to track the effect of changing Solid Ink Densities on ink consumption.

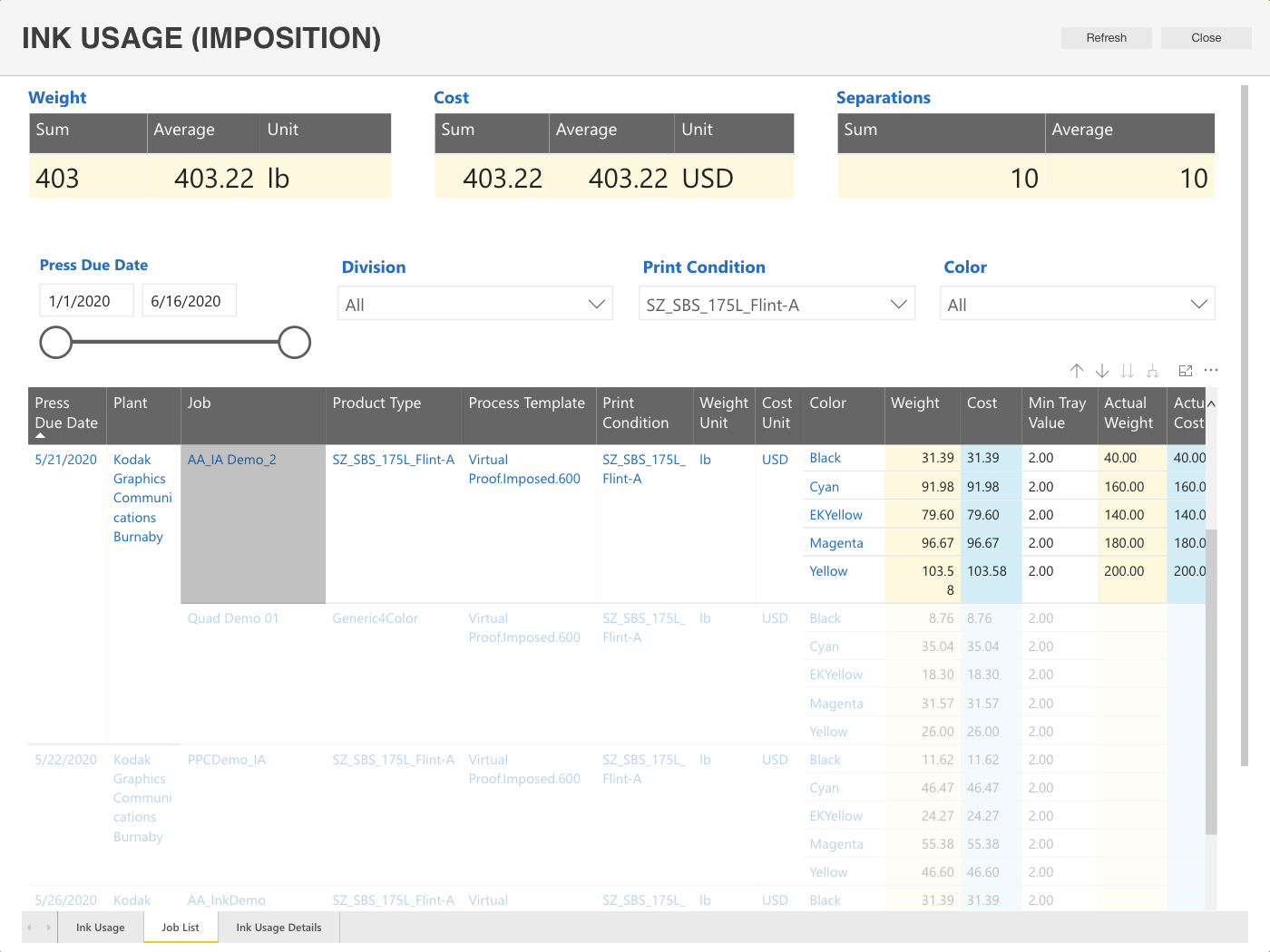

Once Actual Ink Usage has been recorded for a job, Actual Weight and Actual Cost are displayed beside the Estimated Weight and Cost.

Ink Usage dashboard showing Estimated vs Actual Weights and Costs

NOTE: When comparing Ink Estimations that have been generated on a Per Page against a Per Surface there will be differences. This is due to the nature of the process. Per Page estimations will often be rendered at a lower resolution and different screening. Per Surface (Imposition/Layout) estimations will consider a composition of pages (artworks), and structure associated with Press marks (color bars, etc.). The Actual Ink Usage feature takes into account the values associated with a Per Surface and will provide better estimations for Per Page estimation.