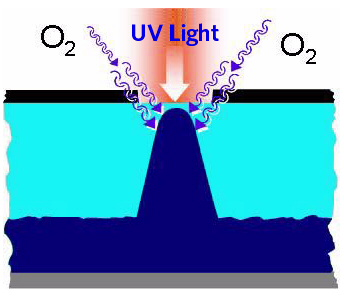

The primary difference between digital and conventional plates is that digital plates have a carbon mask layer covering the plate (instead of film) that is ablated by the digital imager before the plate is exposed to UV light. Digital plates produce a sharper dot on plate through a process called oxygen inhibition, as shown in the following photos.

Ablated mask on digital flexo plate does not shield monomer from oxygen during UV exposure, as there is no clear polyester layer as with film, and no vacuum is used during exposure

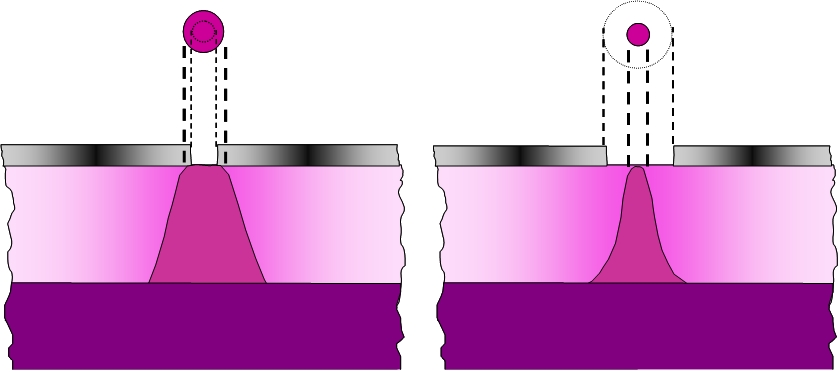

Left: Conventional UV exposure (1% exposure may result in a 2% or 3% dot); right: digital flexo UV exposure (4%-5% exposure may result in a <1% dot)

In the image above, the Illustration on the left shows that conventional film UV exposure results in a dot larger than the opening, because UV light is refracted when travelling through the film base, and cross-linking of the polymer is not inhibited by oxygen due to a vacuum being applied. The Illustration on the right demonstrates that cross-linking is inhibited by oxygen, and the dot is smaller than the opening. This is often referred to as dot sharpening.

For example, if a 5% exposure is imaged on a digital plate, the resulting dot on plate will be something smaller than 5%, depending on the plate type and processing conditions. It is this dot-sharpening process that enables digital flexo to achieve finer highlights and open shadows, but it also requires a recalibration of the platemaking process to compensate for the difference. This calibration can be referred to as a bump curve. (Kodak Maxtone and HyperFlex technology can reduce or eliminate the need for bump curves.) The following table indicates the typical minimum dots that you can expect to hold on a digital plate when using conventional AM screening. Results will depend on the plate types that you use and processing conditions.

LPI | Minimum Dot Value on Mask (%) | Resulting Dot on Plate (%) |

|---|---|---|

120 | 3% | <1% |

133 | 4% | <1% |

150 | 5% | 1 to 2% |

175 | 7% | > 2% |