What is the Prinergy Document Screen Manager?

The Prinergy Document Screen Manager is a tool you can use to define screen information such as ink type, dot shape, angle, screen ruling, and printing method for each color in specific objects in an Illustrator file. When you use the Prinergy Tools Output PDF... function from Adobe Illustrator, screen information is saved in the file and can be applied as Document Screening at the time of output in Prinergy.

Printing Method is an optional tag which can be used to encode Advanced Flexcel NX Tags to be used in TIFF Assembler Plus to automatically apply advanced Flexcel NX screening. (Advanced Flexcel NX Tags are covered in detail in Miraclon TIFF Assembler Plus documentation.)

Key points to remember about applying Document Screening:

- You must press Update after opening an artwork file for the first time, to populate screen parameters in the UI.

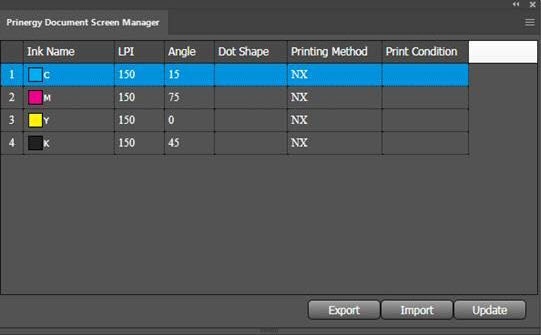

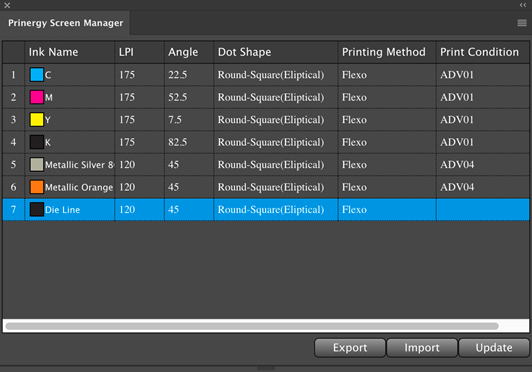

- All of the three main parameters: LPI, Angle and Dot Shape must be filled in for each instance. If any of the three parameters such as "Dot Shape" is left Blank, output will fail at the time of output in Prinergy with an "Invalid Screening" message. Printing Method and Print Condition are optional and can be left blank.

- You must use the Prinergy Tools Output PDF... function to embed Object Screening into a PDF for processing in Prinergy.

- Important note about matching screen angles

- You must keep in mind that Prinergy Output treats angles in object/document screening differently than angles in Prinergy Process Templates. You must adjust object/document screen angles if you wish to match Prinergy screening.

- Historically, Prinergy has assumed that embedded object/document screening was being specified in PostScript applications that calculated angles based on 0 at 3 o'clock and measured counter-clockwise. Prinergy, on the other hand, has always used a coordinate system that sets 0 set at noon and measures clockwise.

- What this means is that if you wish to match object/document screening with Prinergy screening, you must adjust the screen angles being specified in Prinergy Tools.

Sample angle translations to match Object/Document (PostScript) Screening to Prinergy Process Template Screen Angles

ColorObject/Document

Screen AnglePrinergy

Screen AngleC 75 15 M 15 75 Y 90 0 K 45 45

Prinergy Document Screen Manager workflow

- Launch Adobe Illustrator.

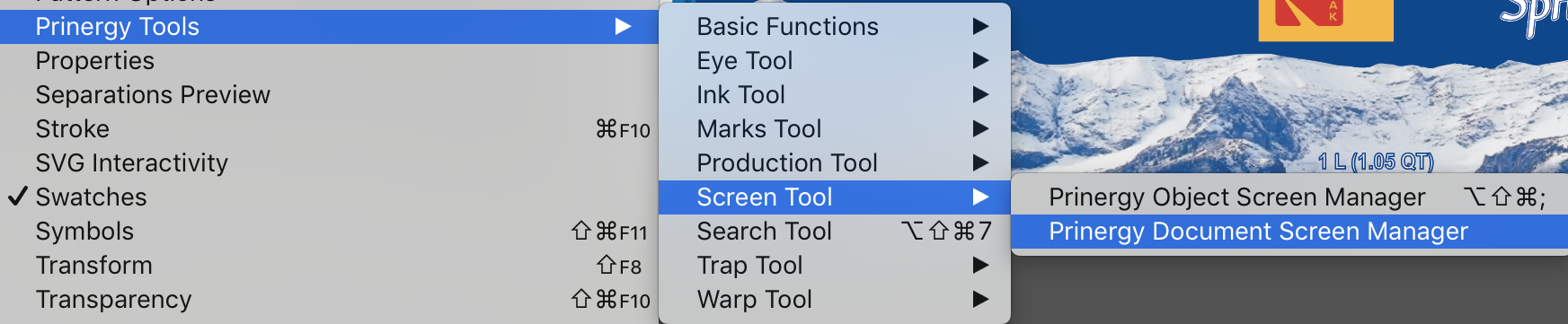

- From the Windows menu, select Prinergy Tools > Screen Tool > Prinergy Document Screen Manager.

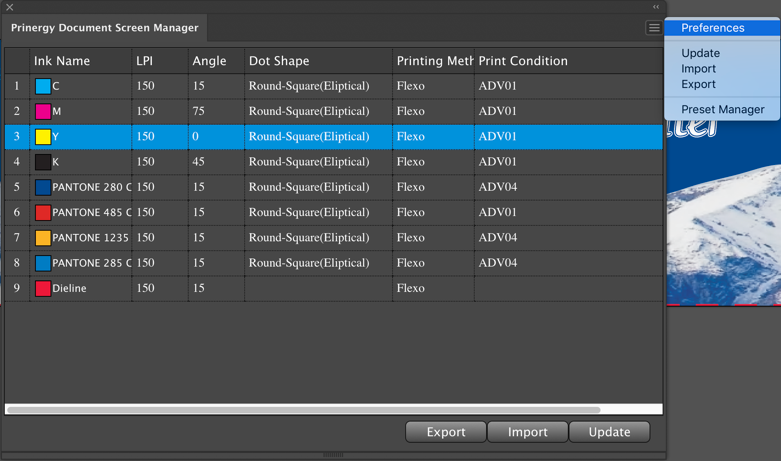

The Prinergy Document Screen Manager dialog box appears. - To set up the default screen parameters, from the side menu, select Preferences and set up the default parameters.

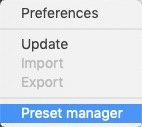

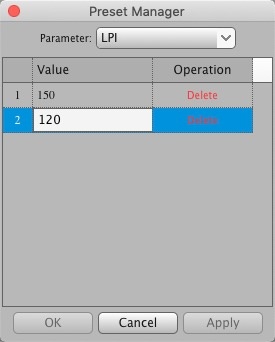

- If desired, predefine the settings used in the Document Screen Manager user interface by selecting Preset Manager from the side menu, and creating settings for the various parameters.

The Preset Manager is also used for deleting parameters that are no longer required. - Open the Adobe Illustrator or PDF file in which you want to set screen parameters.

- To read current information about the inks used in the document, click Update.

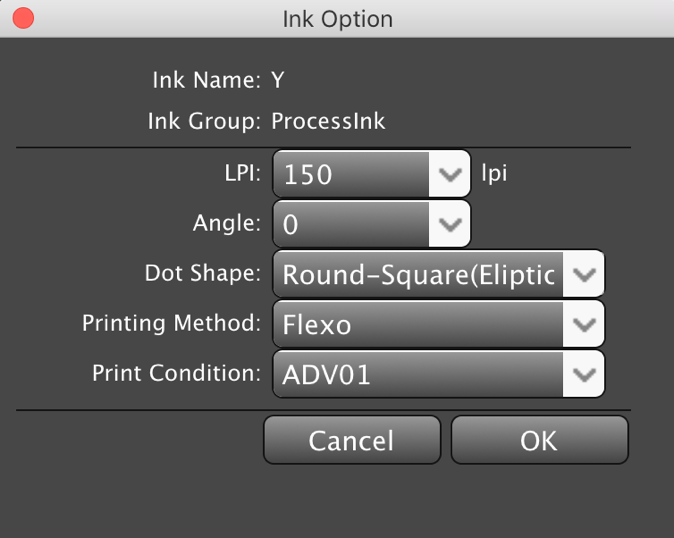

The list of inks will update. To edit the screen parameters for a separation, double-click the ink to display the Ink Option dialog box.

In the Ink Option dialog box, you can select from the list or your can enter new parameters, which will then become available as a choice in the drop-down menus.Ink Name The selected ink. This parameter cannot be edited. Ink Group The ink type. For example: process ink or spot color ink. LPI Select the dot ruling for the selected ink. Angle Select a dot angle for the selected ink. Dot Shape Select a dot shape for the selected ink, or input your own parameter. Printing Method Select a printing method for the selected ink, or input your own parameter. Print Condition Provide print condition information. - When you have completed your edits, click OK and save the parameter ticket as an

.spffile. - From the side menu, click Export and specify the path for saving the parameters.

Note: You can load saved parameters to other documents by clicking Import from the side menu.

- You must use Output it to PDF... from Basic Functions in order to embed screening information in the PDF. If you use the native Illustrator "Save As..." to output as PDF, Prinergy Tools document screening will not be embedded in the resulting PDF.

Use of the XmpMapping.csv file with Prinergy Tools Document Screening.

Document Screening can also be used to automatically apply Prinergy Advanced Screening such as Maxtone CX, Maxtone FX and Maxtone SX. This functionality works together with an XmpMapping.csv file found on a Prinergy Server at C:\Prinergy\CreoAraxi\data\XMPTags. This configuration file allows you to apply document screening that requires additional parameters that cannot be specified by standard document screening tags. Standard document screening only allows users to specify Line Frequency, Angle and Dot Shape, and only a limited number of standard Adobe dot shapes are allowed. The XmpMapping.csv file allows you to create a DotShape name that will be used as a key to supply the other parameters required by advanced screening, such as highlight size.

A sample line in the XmpMapping.csv file that could be used to specify Maxtone SX screening is:

SXR3X3,Maxtone SX,Maxtone SX CMYK 15-45-0-75,Round1,3x3

You would specify the name SXR3X3 as the Dot Shape, and this would apply the actual Prinergy dot shape name (Round1) and specify a Maxtone SX stochastic highlight size of 3x3 pixels. Whenever changes are made to an XmpMapping file on a Prinergy system, you must restart all Prinergy JTPs in Prinergy Administrator, to allow the changes take effect.

Reading Esko screen information from an Illustrator File

Open the document that contains Esko's screen information, and click Update. The Esko screen information will be read in to the Document Screen Manager window. If you save this document again, Esko's screen information will not be overwritten, and the original specified screen information will be saved.