Resources for these procedures: Kodak or third-party media representative, with assistance from Kodak service representatives.

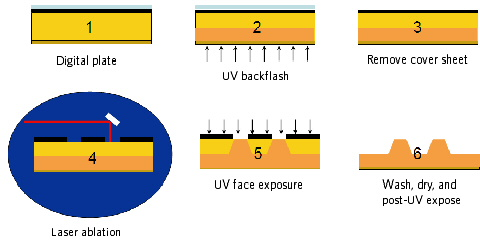

Digital flexo plates are created by exposing media to ultraviolet light after the ThermoFlex has ablated the mask. The UV light creates polymer cross-linking between molecules, causing the plate media to harden in the areas exposed to UV light. The exposed face areas will carry and transfer ink, and must be strong enough to resist press impression without deforming or moving, which would cause undesirable print artifacts and excessive dot gain. It is important to note that the back of the plate material must also be exposed to UV light to create a strong base onto which the image areas on the face of the plate can bond.

Figure 1. Digital plate exposure process