HyperFlex was originally developed to improve the formation of Maxtone on plate and to improve Maxtone's performance on press. However, even in cases where Maxtone is not used, HyperFlex can be used to improve the formation and performance of full AM printing.

AM dots suffer from insufficient UV energy reaching the plate in highlight areas. As AM highlight dots become smaller, the amount of overall UV energy is reduced, and highlight dots will no longer form properly or may be too weak to withstand impression on press. With HyperFlex, you can apply UV light valve technology to raise the energy threshold, and allow dots to polymerize properly. In some cases, the use of HyperFlex might allow a slightly smaller AM minimum dot value. The main advantage is that using HyperFlex with AM dots builds up the floor between dots, increasing the slopes of the shoulders and causing stronger polymerization of the individual halftone dots. This increases consistency of development over time, better resistance to solvent attack and washup, and cleaner printing. Plates will last longer and print better.

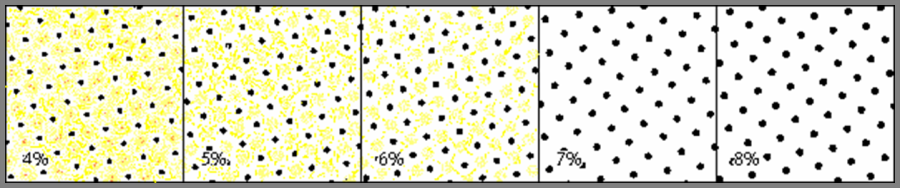

The figure below is a simulation of how extra energy is applied to the highlight area, then feathered off as you move up the tonal range.

HyperFlex Advanced light-valve technology can be used to direct extra UV energy and activate the plate and produce stronger, better-formed halftone dots

With traditional technologies, all you can do to improve the minimum dot is to create a bump curve, which will increase dot gain at the highlight. With HyperFlex Advanced, you may be able to maintain a smaller dot, and print with less dot gain.

Left: Analog AM dots need bump curve applied, which creates considerable dot gain; right: AM with HyperFlex allow the smallest possible minimum dot

For best results, you should use HyperFlex with AM dots in the merge position. To ensure best consistency of results in the highlights, you should run HyperFlex Advanced up to the 15%–20% dot. Fingerprint by running out step tests with different amounts of HyperFlex Advanced applied. View plates in transmission on a light table and examine them to see where dots come up to full relief height and where they appear to be well formed. To confirm settings, print tests on press and confirm resulting values with visual inspection and densitometer readings. From these tests, you can determine the lowest possible minimum dot value.