PrintLink digital ink-profiling software can generate JDF (Job Definition Format) and PPF (Print Production Format) files that specify ink coverage information for digital ink key preset systems. This feature reduces misprints and makeready times.

PrintLink controls are found in the PrintLink section of the final output process template.

Note: PrintLink is not associated with PrintLink Graphic Arts Placement Services.

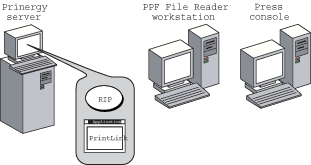

PrintLink uses three computers in your printing process:

- Workshop workstation (a Prinergy server and a Prinergy secondary server running a RIP)

- PPF file reader workstation

- Press console

Benefits of using PrintLink

Traditionally, a plate scanner is used to produce ink key presets. PrintLink is a digital replacement for a plate scanner and provides more accurate coverage information. Instead of scanning an imaged plate to estimate ink coverage, PrintLink uses the same digital source data that Prinergy uses to image the plate.

PrintLink computes the ink key settings while your output device images the plate. PrintLink stores the ink key coverage data and identification information in the PPF file. Thus, you can achieve a level of accuracy and repeatability not found with traditional plate scanners. In addition, you eliminate plate scanning time and risk of plate damage.

For presses without CIP3 or CIP4 ink readers, Prinergy can create user-readable ink key settings, which you can manually enter in the press console. This feature reduces makeready time by ensuring that ink keys are accurately set without the costly investment of purchasing a press with a CIP3 or CIP4 ink reader.

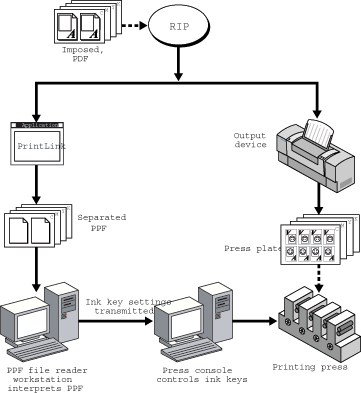

How PrintLink works in a Prinergy workflow

- Your imposed PDF files are sent to the RIP on a secondary server.

- The RIP on the secondary server receives the imposed files, RIPs the data, and delivers the high-resolution raster to your output device.

- While the RIP delivers the raster for plate imaging, PrintLink generates a PPF file, one file per separation.

- The resulting separated PPF file is sent to the PPF file reader workstation.

- The PPF file reader workstation interprets the ink coverage data.

- The digital ink key settings are transmitted to the press console, which controls the ink keys based on the PPF information it receives.

Ink reports

You can generate an ink report from the PPF files produced by PrintLink. The ink report is a text-based report that describes the area of ink coverage (in square centimeters and inches) and the percentage of the plate covered.

Custom PPF file

PrintLink produces PPF files that comply with the International Cooperation for Integration of Prepress, Press, and Postpress (CIP3) PPF file specification. CIP3 has established an open standard for exchanging information among print production devices from multiple vendors, including platesetters, presses, and finishing equipment.

The standard specifies the Print Production Format for communicating ink coverage information, printing form geometries, and other information for digital ink key presets. Although PrintLink adheres to this standard, some press interfaces require additional information from the PPF file. To support these requirements, certain CIP3 tags in the PPF file can be customized.