Rotation is a complex issue in layout and workflow software. There are many ways to consider rotation, and many ways that it could be applied. Most operators encounter rotation when sending output to a laser or inkjet printer. The software for printers typically displays one element as static: either the content or the media. The other element is rotated. If both elements could be rotated, it would make creating layouts much more difficult.

Prinergy Evo uses a similar strategy: it keeps media or file dimensions static and rotates the layout content within those static dimensions. In Prinergy Evo, this is how rotation works:

- Alignment is applied.

- Rotation is applied to the layout so that it rotates within the position it has been aligned Alignment and orientation are effectively independent. Alignment is always relative to the defined media or file size.

- Finally, scaling settings are applied so the image scales using the orientation and alignment you

Rotating TIFF Files For Efficient Processing

Files sometimes need to be written in a particular way for efficient processing at output. This is particularly true when using indirectconnectivity in which

Prinergy Evo must write a TIFF to the output device. Prinergy Evo writes TIFFs with horizontal stripes. For many inkjet printers and capstan imaging devices, this matches the fast scan direction of the imaging headwith a heads up image. Fast scan refers to the direction that imaging occursquickly in. For more information, see the following diagrams.

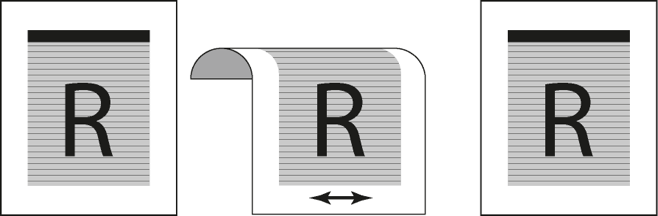

Capstan imaging devices

For capstan devices, the imaging head moves across the media perpendicular to the path the media moves through the device.

- Left: Shows the stripe direction relative to the output image for efficient processing.

- Center: Shows the relationship between fast scan and data written for efficient processing.

- Right: Shows the file as generated by Prinergy Evo for efficient processing at output.

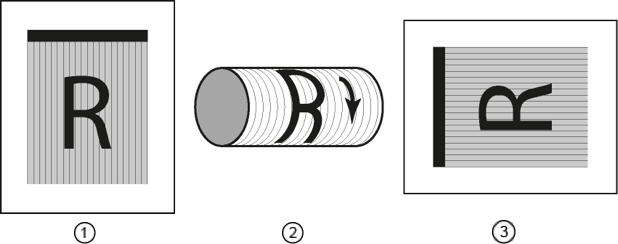

Drum devices

In drum devices, the drum spins faster than the imaging head moves across it, so the fast scan direction is the direction of drum rotation. The direction of drum rotation is also the same direction as the media path, so the fast scan direction in drum devices is along the opposite axis from capstan devices.

- Shows the stripe direction relative to the output image for efficient processing

- Shows the relationship between fast scan and data written for efficient processing.

- Shows the file as generated by Prinergy Evo for efficient processing at output.

To generate an appropriate TIFF file with stripes that are the direction of fast scan during output on drum devices, you must configure layouts that are transverse to the actual device media path. These arecases in which you have to send generic TIFFs but don’t have knowledge of the device’s specific file requirements. This introduces acomplication for drum devices because they image with vertical data stripes relative to image content. To output the TIFF file correctly, you must introduce a 90- or 270-degree rotation in the output TIFF.

When you select Digital this is fairly straight forward: you configure a Preps device and signature that matches your intended output file size,submit them to Prinergy Evo and set a 90- or 270-degree rotation.

When you select Cut sheet there is an additional challenge. To output afile with the correct dimensions that also matches the fast scandirection, swap the dimensions in the Max Width and Max Height fields in the Layout section of the process template. You are effectivelyrotating the media by swapping values to compensate for the way theTIFF needs to be read by the output device.

Direct connectivity

When using direct connectivity, these adjustments are hidden. For example, when outputting to a Kodak TrendSetter, Prinergy Evo automatically configures the data so that the image is efficiently output on the device.